My Approach

To keep the DIGIT mechanical assembly low-cost at scale, it was designed for single-pull injection molding. With slight modifications the design also is compatible for 3D printing.

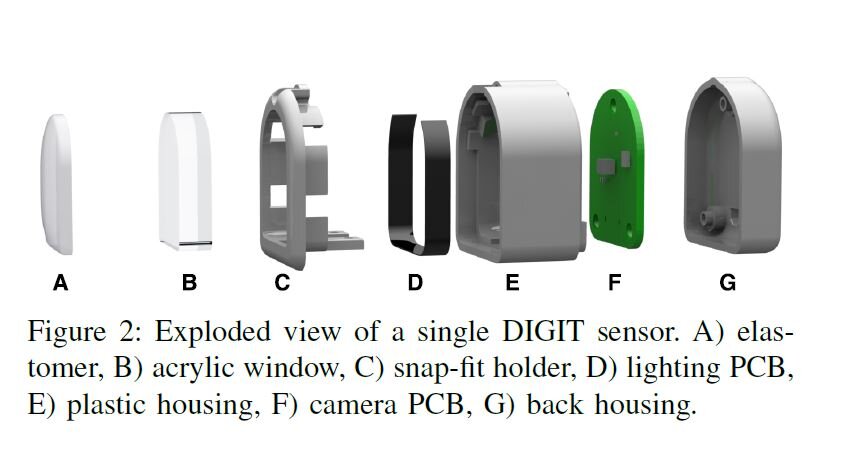

The clear acrylic window is press-fit into the front cover, and together they are secured to the body of the housing with snap-fits and a single screw. The lighting PCB is snuggly fit along a track in the body of the housing with openings for the LEDs to provide light through the side of the acrylic. The camera PCB and the back cover share the same mounting screws to reduce parts and assembly.

It was important to design a cover that could be easily attached or removed. The task-specific elastomer is adhered to the clear acrylic window, and this component will need to be swapped out due to wear-and-tear or if a new elastomer with different material properties is needed.

The design went through several iterations, but after testing each iteration a reduction of overall size was prioritized over a larger viewing window.