Approach

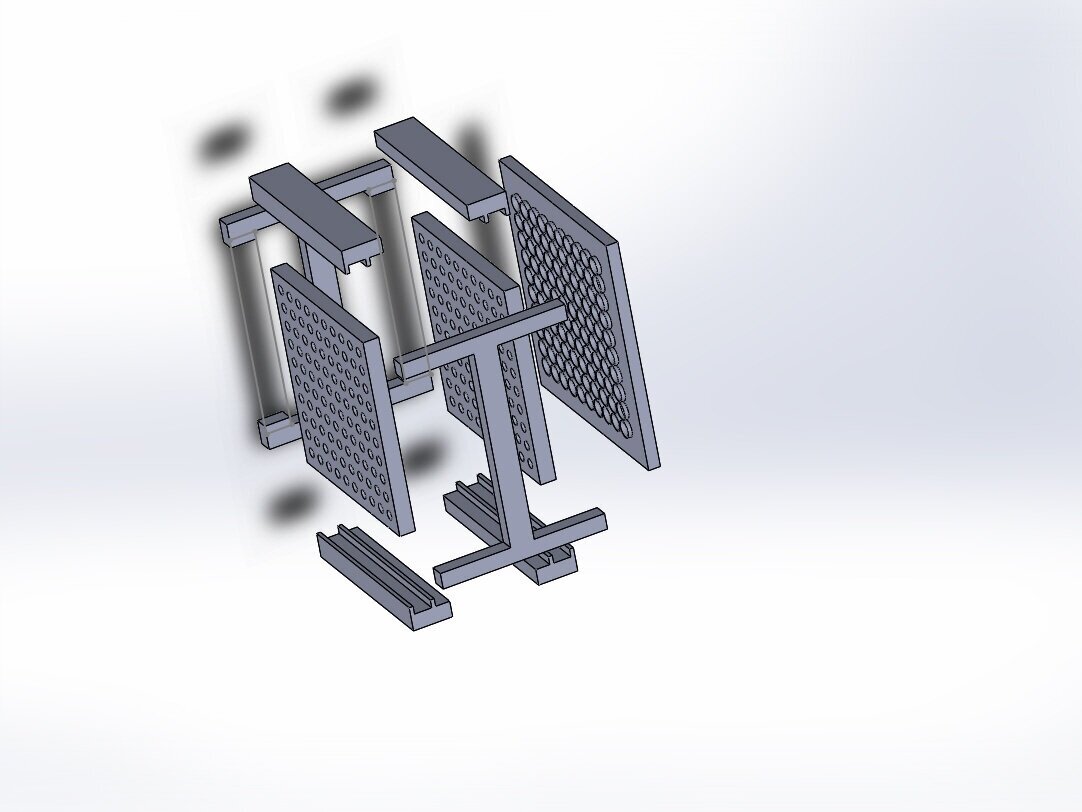

Off the shelf components for these unique test tubes couldn’t be found, so parts were designed from scratch. To keep costs down the final product would use durable 3D printed material and laser cut acrylic instead of injection molded plastic. The body of the RAFTT and the control box were designed for and made by 3D printing. The stand and motor housing was designed for and made by laser cut acrylic. The entire system can be assembled or disassembled with a single allen wrench. The major electronic components included an arduino, 16x2 LCD, voltage regulator, and a rotary encoder.

Ease of Use

The device needed to be easy to use and intuitive for any researcher to use with minimal training. While the lab only needed the device to be set to a constant speed, frequency, and angle, I programmed the micro controller with a menu system in which the user could set each value. This design choice was to prevent unforeseeable issues and allow variations of the experiment. In addition, a USB connection is available on the control box if any firmware updates are needed.